Build To Print (BTP)

- Home

- New Product Development

BTP Process Flow

-

Receipt and Review of Fabrication Drawings

We begin by receiving the fabrication drawings from the customer. These drawings contain all the necessary specifications and details required for the manufacturing process.

-

Procurement of Raw Materials (RM) with Certificate of Conformance (CoC)

Next, we procure the necessary raw materials, ensuring that each material comes with a Certificate of Conformance (CoC) to verify its quality and suitability for the project.

-

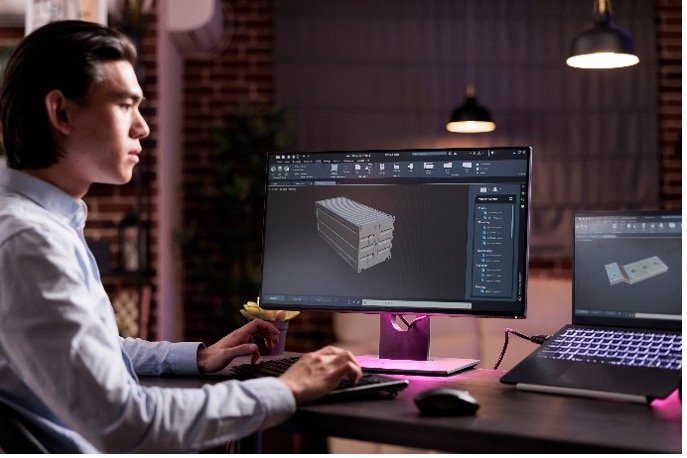

CNC Programming as per Drawing with Geometric Dimensioning and Tolerancing (GDT)

Our team then creates CNC (Computer Numerical Control) programs based on the drawings, incorporating Geometric Dimensioning and Tolerancing (GDT) to ensure precision in the manufacturing process.

-

Fabrication as per the Drawing

Using the CNC programs, we fabricate the components exactly as specified in the customer-provided drawings, ensuring adherence to all dimensions and tolerances.

-

Quality Check for Machined Parts

After fabrication, each machined part undergoes a thorough quality check to ensure it meets all specified criteria.

-

Post-Fabrication Processes – Drilling, Tapping, Deburring, etc.

Post-fabrication processes such as drilling, tapping, and deburring are performed to refine and complete the parts as per the requirements.

-

Quality Checks for Fabricated Parts

Further quality checks are conducted on the fabricated parts to ensure they are defect-free and meet all specifications.

-

Final Finishing like Plating, Painting as per Drawing

The parts then undergo final finishing processes such as plating and painting, following the specifications provided in the drawings.

-

Internal Quality Check for Finished Parts

An internal quality check is conducted on the finished parts to ensure they meet the highest standards of quality before being offered for external quality control.

-

Offering for External Quality Control (QC)

The finished parts are then offered for external quality control inspections to verify their compliance with the customer’s specifications.

-

Packing and Dispatch

Finally, the parts are carefully packed and dispatched to the customer, ensuring they reach their destination in perfect condition.